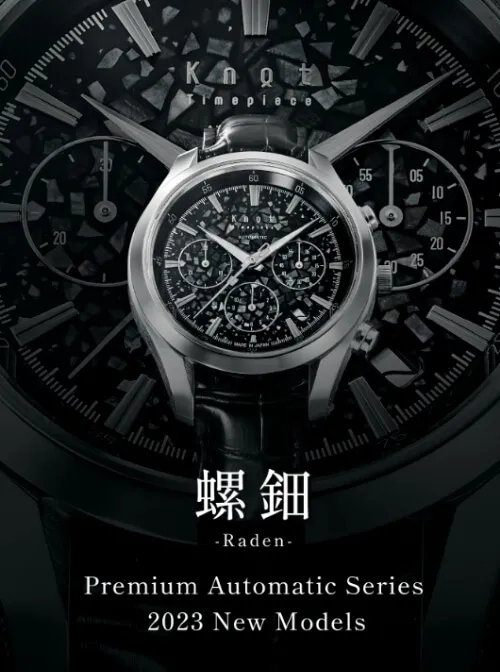

Premium Automatic Mechanical Chronograph Japan Concept

Premium Automatic Mechanical Chronograph Japan Concept

Premium Automatic Mechanical Chronograph Japan Concept

Premium Automatic Mechanical Chronograph Japan Concept

2094Point

SKU: ATC-40SVJPBKGS_LD-16SVSV-ATC-40

ATC-40SVJPBKGS_LD-16SVSV-ATC-40

2094Point

Couldn't load pickup availability

Limited Edition Model, Japanese Lacquer

This is the collaboration of Knot's flagship model "high performance mechanical watch" and Japan's representative traditional craft "Japanese Lacquer (also called "Urushi" in Japanese)".

The beautiful "Jet Black" is developed by the repeated painting, drying and sharpening by the skilled Japanese craftsmen. Then covered with gold powder scraped from gold ingots, and the depth is brought out by the overlapping of fine particles for you to enjoy the unique texture of URUSHI dial.

SPEC

- Case

- SUS316L / Silver Polish

- Glass

- Sapphire glass

- Dial

- Urushi Jet Black

- Hands

- Silver

- Diameter

- 40mm

- Thickness

- 13.5mm

- Weight

- 91.5g

- Movement

- cal.NE88 / SII

- Water resistance

- 10ATM

- Precious Stone

- 34 Stones

- Time Precision

- Average day difference : -10 seconds to +30 seconds

- Frequency

- 28800 vibrations / hour

- Duration

- 45 hours

- Warranty Period

- 3 years for movement

※Please note that straps are sold separately. You can choose freely according to your own preference.

※This product can not perform “Engraving Services” because the back cover is glass specification.

The beauty of the Urushi lacquer dial

Urushi is a paint created from the sap of the lacquer tree.

Its history is ancient, with the world’s oldest

lacquerware believed to be a 9,000-year-old burial ornament discovered

in Japan. Lacquer crafts are used in many parts of Asia, and it is a technique that has become synonymous with

Japan –

so much so, that in other countries the word “Urushi” (lacquer) is sometimes translated simply as “japan”

alone.

This new collection is the latest in Knot’s flagship Premium Automatic Series, acclaimed for the

beautiful traditional

craft techniques incorporated on their dials. The two new watches feature Urushi lacquer dials in vermilion red

and jet

black, sprinkled with gold and silver powder on both models.

The ever-enduring,

ancient allure of lacquer

The intricacy of the coating process is such that the ancient tradition of lacquer can only be undertaken by craftsmen who have acquired specialist, advanced techniques and skills. Unlike synthetic paints, lacquer is tremendously durable, with lacquer products from 1,000 years ago still preserved to this day. The ‘three-dimensional’, ‘moist’, and ‘deep’ properties of its texture also make it completely unique. Lacquer is additionally considered a good-luck charm for protection, as its ingredients are said to keep insects at bay, and in recent years the antibacterial properties of lacquer have also garnered interest. Most lacquer used in Japan is produced in China, but this timepiece employs precious Japan-made lacquer – the same that is used to preserve and repair Japanese national treasures and cultural heritage.

An opulent, luxurious 99% pure gold and 100% pure silver overlay

Using the distinguished “Maki-e” technique – where powder from crushed shells is delicately and purposefully

scattered

to create pictures – the watch dial is sprinkled with resplendent gold and silver powder. The gold and silver

overlay is

then further embellished with a final silver finish, to give the pure gold shimmer an even greater

emphasis.

The gold and silver powder is known as “round powder”, since it is made by grinding down a block of

metal to a fine

powder using a file, and then rounding it to create a spherical shape. Both the gold and silver powers are of

the

highest grade.

GRADIENT FINISH

The gold and silver powder is arranged in an attractive gradient which transitions from the center to the outer

edge.

This gradation has been refined by Knot’s product designers for optimum readability of the hour markers, and hand

crafted by traditional artisans.

This intricate effect, meticulously adjusting the amount of powder dispersed,

is a result which can only be achieved by

the skilled hand and intuition of a master craftsman.

Jet black and vermilion red:

the traditional colors that

make gold and silver shine

The watch is available in the two quintessential colors of Urushi lacquer. The first is jet black lacquer, with deep contrast that can only be expressed through this material. When written in Japanese, the characters are the same as those used to describe pitch darkness, or the beauty of pure black hair. The second is vermilion red lacquer. In ancient times, this color could only be used by individuals of high rank, as the pigment used to make vermilion was extremely rare.

Case back with "Urushi" lettering

The model based on the three-hand AT-38 has a see-through case back which

allows you to observe the movement of the

Japanese-made high-beat movement.

The case back features the Japanese character “漆” for “Urushi” within the

glass, evoking a Japanese aesthetic.

※Please note that the ATC-40 chronograph model does not have a

see-through back.

AT-38SVJPBKGS

AT-38SVJPRDGS

ATC-40SVJPBKGS

ATC-40SVJRRDGS

The Urushi dial is also available as a Chronograph type model,

in both

vermilion red and jet black

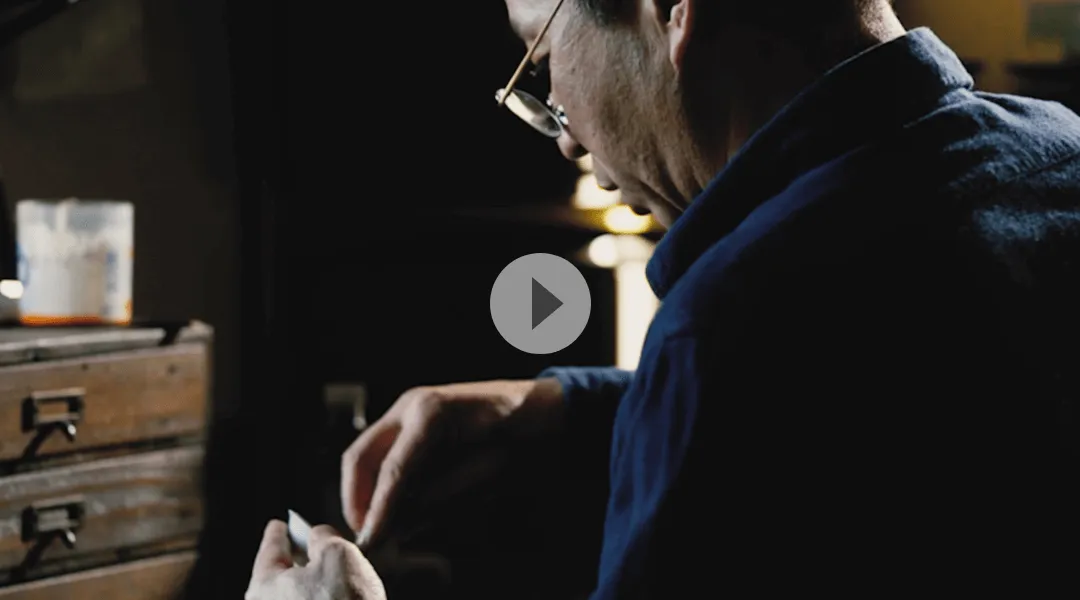

OUTSTANDING SKILLS OF TRADITIONAL AIZU ARTISANS

The “traditional artisan” title is only awarded to technicians working in the manufacture of traditional crafts who possess advanced artisanal skills and techniques. The dial has been realized in collaboration with Nobuichi Otake, a traditional artisan whose style employs sophisticated technical skills and an original sense of style.

Nobuichi Otake, Traditional Artisan

Born in 1959 in Fukushima (the area formerly known as Aizu)

Upon completing

high school, Nobuichi Otake had wanted to

pursue a career in painting – something he had loved ever

since he was a child – and became an apprentice to Sone Takuo, a Contemporary Master Craftsman of Aizu

lacquerware.

After five years and five months as an apprentice, he became an independent craftsman of Aizu

Maki-e lacquerware,

renowned for its elegant and ornate design.

Nobuichi Otake’s work

A craftsman’s production process for Maki-e dials,

through every

intricate step

1.Base coating

Lacquer is applied in multiple layers, dried, and polished to a smooth surface. Once the thickness has been adjusted, it is coated again with fresh lacquer so that the gold and silver powders can adhere to it. The lacquer must be applied evenly and with just the right thickness, in order to obtain the desired finish.

2.Gold and silver powder distribution

Gold and silver powder are placed into a cylinder and sprinkled in turn. The amount of gold and silver powder is controlled in a fine balance as it is distributed in a gentle gradation from the center. The highly skilled craftsman subtly adjusts the amount of powder by tapping the powder cylinder with his finger to sprinkle it.

3.Coating application

After the lacquer has dried and the gold and silver powder has completely set, another layer of lacquer is applied. This fills in the gaps between gold and silver particles to create a uniform dial surface which combines the brilliant lacquer and glittering powder.

4.Polishing

After the layers of lacquer have thoroughly dried, the surface is polished to produce a cross-section of gold and silver powder. Due to the rounded shape of the gold and silver powders, a slight change in the degree of polishing alters the appearance of the cross-section of the powder. It is therefore a process that demands the utmost sensitivity.

5.Lacquer adjustment

The lacquer surface is polished to remove any scratches and make the cross-section of gold and silver powder shine beautifully. This adjustment is an important step which determines the final appearance of the dial.

Case finished with the advanced Sallaz mirror polishing technique

from

Hayashi Seiki Seizo, exclusive to the Premium Automatic Series

Sallaz mirror polishing is an advanced finishing technique which produces a beautiful flat surface with clean edges and zero distortion. There are very few craftsmen who are able to apply Sallaz mirror polishing, which makes it a rare and precious sight. The name “Sallaz” was originally derived from Swiss processing equipment, but it is now only found in high-end Japan-made watches. The ability to give different looks to the same material by carefully polishing each part is a highly sophisticated technique performed exclusively by the experienced technicians at Hayashi Seiki Seizo.

Exclusive Package

Exclusive Package

The watch is presented in a box exclusive to the Premium Automatic Series, in a limited edition Urushi sleeve. An original watch cloth is also included.

The watch is presented in a box exclusive to the Premium Automatic Series, in a limited edition Urushi sleeve. An original watch cloth is also included.

Coordination

In combination with the striking impression of the Premium Automatic Series, we can recommend the exclusive Smart Fit Bracelet for its reassuring weight and attractive shape, or the Cordovan Strap with its solid thickness and luxurious feel.

Specification

AT-38SVJPBKGS / AT-38SVJPRDGS

【Case】316L stainless steel

【Crystal】Sapphire glass (single-sided anti-reflective coating)

【Water resistance】5 ATM (water resistant to 5 bar)

【Movement】cal. 9015 (8 vibrations per second, 42-hour running time)

【Number of jewels】24

【Accuracy】Average -10 seconds to +30 seconds per day (at room temperature between 5°C and 35°C)

【Display features】3 hands (hours, minutes, seconds), date

【Warranty period】3 years (for movement)

【Size and weight】Diameter 38mm, thickness 10mm, weight 50g

ATC-40SVJPBKGS / ATC-40SVJRRDGS

【Case】316L stainless steel

【Crystal】Sapphire glass (single-sided anti-reflective coating)

【Water resistance】10 ATM (water resistant to 10 bar)

【Movement】cal.NE88 (8 vibrations per second, 45-hour running time)

【Number of jewels】34

【Accuracy】Average -10 seconds to +30 seconds per day (at room temperature between 5°C and 35°C)

【Display features】6 hands (hours, minutes, small-second, stopwatch hand (seconds), 30-minute hand, 12-hour hand), date

【Warranty period】3 years (for movement)

【Size and weight】Diameter 40mm, thickness 13.5mm, weight 91.5g

STANDARD MODEL

Standard automatic model line up suitable in various situation.

PREMIUM STRAP

A selection of high-quality straps suitable for premium automatic models